Swivel fittings stand as indispensable components within fluid transfer systems, crucial for enhancing the efficiency and durability of hoses and tubing. These specialized fittings are designed to allow seamless rotation between connected parts, thereby preventing the hoses from twisting or kinking during operation. This article provides a detailed overview of swivel fittings, covering their design, function, and the various types available, with a focus on the innovative offerings by Taimi Hydraulics.

What Are swivel fittings?

Swivel fittings are engineered to facilitate smooth connectivity in fluid transfer systems, linking hoses, tubing, or other components. These fittings are comprised of two rotatable sides: a stem and a housing, each featuring threaded ends for secure attachment to hoses and tubes. This structure is essential for maintaining unimpeded fluid flow while preventing mechanical stresses that could compromise system integrity.

Understanding the Functionality of swivel connectors

The primary function of a swivel connector is to prevent hose twisting, a common issue that can significantly reduce the service life of high-pressure hoses. Field tests indicate that even a torsion angle of 5° can shorten a hose's service life by up to 70%, escalating to 90% with a 7° twist. By eliminating twisting, swivel connectors enhance reliability, reduce downtime, and boost productivity across various mechanical applications.

Exploring different types of swivel

Swivel fittings are generally crafted from steel for enhanced durability, with carbon steel being the predominant material. However, stainless steel variants are sometimes employed in marine and offshore settings. The two principal types of swivel fittings are:

- In-Line Swivels: These are designed for a direct fluid path without directional changes.

- 90° Swivels (Elbow Swivels): These fittings alter the fluid's flow direction by 90 degrees, accommodating different installation needs.

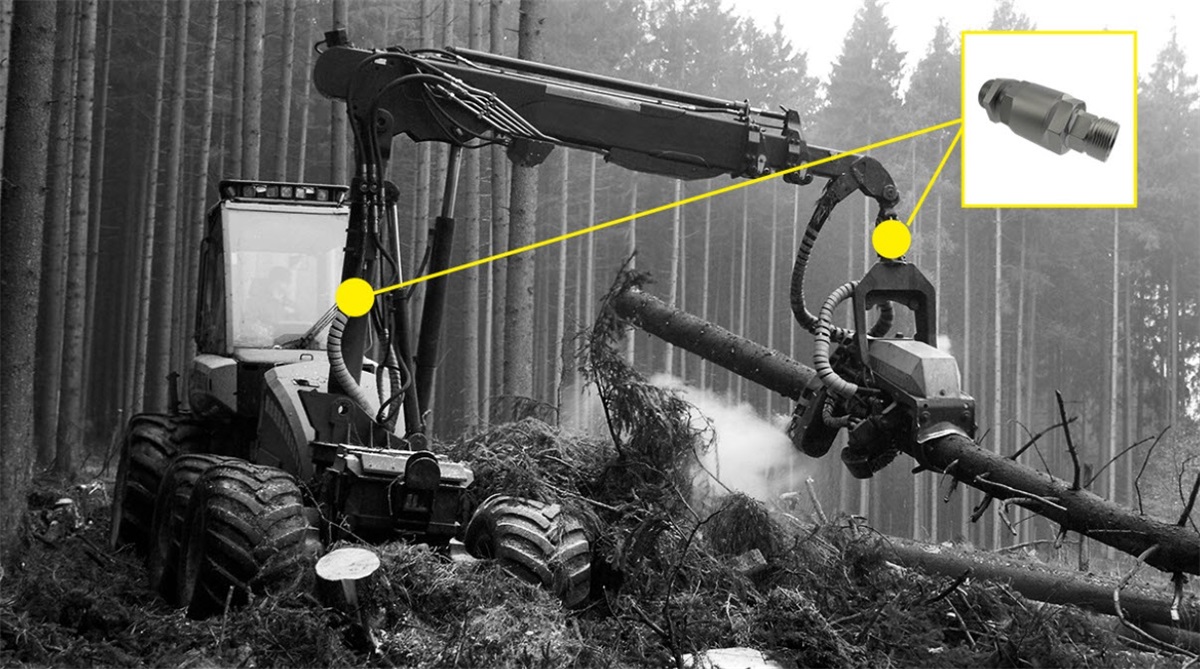

Taimi Hydraulics has introduced a patented cartridge swivel that integrates seamlessly into hydraulic manifolds via a screw-in connection, providing a robust solution capable of handling side loads and pressures up to 400 bar (6000 PSI). This design is particularly beneficial for varied application requirements, notably in forestry machinery.

Size variations in swivel

Swivel fittings are available in a multitude of sizes and designs, ranging from 3/8 inch to 2 inches, to accommodate diverse application requirements. The selection of the appropriate size and type depends on the specific operational demands and environmental conditions of the application.

Want to Reduce Downtime Caused by Hose Failures? Explore Our Swivel Fitting Solutions!

Discover swivel fittings designed to prevent hose twisting and enhance fluid transfer efficiency.

Upgrade your system

Why Opt for Taimi swivel fittings?

Choosing Taimi swivel fittings brings several advantages, primarily due to their innovative design features, including:

- Pressure Spike Protection™: Guards against damage from sudden pressure increases.

- Triple Seal Leak Protection™: Ensures exceptional leak resistance.

- Ball-less Design: Unlike traditional swivels that use ball bearings prone to wear and failure, Taimi’s unique design offers enhanced durability and reliability.

The advanced technologies employed in Taimi swivels ensure they can withstand significant side loads and tensile stresses, substantially extending their service life compared to traditional products. Taimi's swivels are designed to last 8 to 12 times longer than those of competitors, providing what Taimi describes as "Hydraulic Peace of Mind." Service life of these outstanding items can be further extended by means of seal kits that allow replacement of internal seals when necessary.

Conclusion

Swivel fittings are a foundational component in fluid transfer systems, vital for maintaining operational efficiency and extending the longevity of system components. With their robust design and advanced technology, Taimi Hydraulics leads the market in providing durable and efficient swivel fittings that meet the demands of various industrial applications. By choosing Taimi’s innovative solutions, industries can achieve not only enhanced system reliability but also significant operational advantages.

Ready to learn more about our products?

Our team is here to guide you and offer tailored solutions to fit your needs.

Contact Us