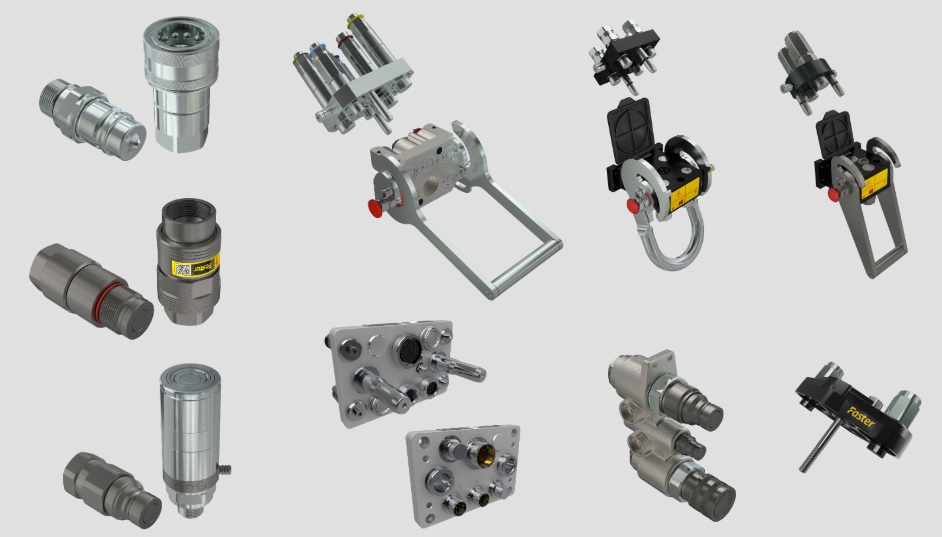

In hydraulic systems, reliable solution are crucial to ensure safety, efficiency, and leak-free performance under high pressure. Connectors and quick couplings enable fast, secure assembly of system components, minimizing downtime and maximizing productivity.

What are connectors in hydraulic?

Hydraulic connectors are components designed to join hydraulic system elements like hoses, tubes, pipes, pumps, valves, and cylinders, enabling leak-resistant fluid transfer under high pressure. They ensure secure connections while maintaining system integrity and pressure.

What are quick hydraulic couplings?

Quick hydraulic couplings are specialized fittings designed for rapid connection and disconnection of hydraulic fluid lines without tools, minimizing fluid loss and maintaining system integrity. They consist of two parts: a male (plug/nipple) and female (socket) component that form a secure, leak-resistant seal when joined.

What type of fittings are used for hydraulics?

Hydraulic quick couplers allow for fast, safe connection and disconnection of fluid lines without leaks. They improve equipment efficiency, minimize downtime, and prevent contamination. There are different types of hydraulic quick couplers, the most common are poppet, flat face, and threaded flat face couplers, each with specific advantages depending on the application.

Poppet quick coupling

Poppet quick couplings use a spring-loaded internal valve (the "poppet") that ensures secure sealing and reliable performance, even under high pressure. This system is robust and reduces the risk of seal extrusion. They are widely used in agriculture, oil & gas, and other industrial applications. Faster offers various series with poppet valves, including NV, HNV, ANV, AGRI, OGV, and VVS.

Flat face hydraulic couplers

Flat face couplers are designed to eliminate fluid loss during connection and disconnection, and to prevent the inclusion of air or external contaminants. Their flush surfaces are easy to clean, making them ideal for environments where hygiene and contamination control are essential, such as construction and forestry applications.

Threaded flat face couplers

Threaded flat face couplers, also called screw-to-connect couplers, offer the benefits of flat face design with added mechanical strength. The threaded connection resists stress and vibration, preventing premature wear. They are ideal for heavy-duty applications and construction equipment operating under high pressure and frequent mechanical shocks.

Hydraulic solutions: reliable connectors and couplings

Boost performance and prevent leaks with Faster’s durable hydraulic connectors and quick couplings.

Explore Solutions

How to maintain hydraulic connections

Regular maintenance of hydraulic quick couplers is critical to prevent leaks, extend lifespan, and ensure operational efficiency. Key steps include visual inspections for damage, checking oil leaks, and cleaning couplers before each use to avoid contamination. Protective dust caps shield coupler halves from debris that can degrade o-rings and seals, causing leaks and reduced machinery performance. The replacement of worn components using spare kits or the entire coupler is definitely a good practice that allows to minimize downtime and to enhance long-term reliability, safeguarding hydraulic systems from costly failures.

How to install hydraulic connections

Proper hydraulic connection installation requires meticulous care. Clean coupling cavities thoroughly to prevent contamination and ensure secure connections. Before operation, inspect fittings for wear and replace compromised parts to avoid leaks or failures. Tighten couplings to manufacturer specifications without over-torquing, and never rotate them under pressure to prevent damage. These steps maintain system integrity, reduce downtime, and enhance safety during hydraulic operations.

Ready to learn more about our products?

Our team is here to guide you and offer tailored solutions to fit your needs.

Contact Us