Automatic Custom Multi-Connections play a crucial role in modern industrial environments. These systems are specifically designed to facilitate connectivity in challenging conditions, ensuring safety, efficiency, and reliability.

This article provides an overview of their general aspects, applications, features, components, and selection tips.

General aspects

Automatic custom multi-connections are particularly suitable for environments with difficult access, extreme temperatures, for ease of use when there are high connection forces, or very frequent connections/disconnections. In these scenarios, a hydraulic multi coupler can be exceptionally beneficial. More in general, these multi-connections are used in all situations where a human operator has no access to the system for safety reasons (dangers and/or risks for human health).

Automatic custom multi-connections eliminate the need for manual connection and disconnection, save time and effort and provide a quick connection with no risk of mistakes. Designed for integration in automated systems, they are able face the challenges of the factory of the future.

Applications in various industries

The automatic multi-connections are widely used in the following sectors:

- plastic industry (injection presses, roto moulding machines, etc);

- automotive industry (end of line engine test, aluminium forming);

- steel industry (rolling mill).

In general, whenever setup times are to be optimized and cross-connection of hoses is to be avoided, the coupling process is performed thanks to an automatic multi-connection.

Features and components

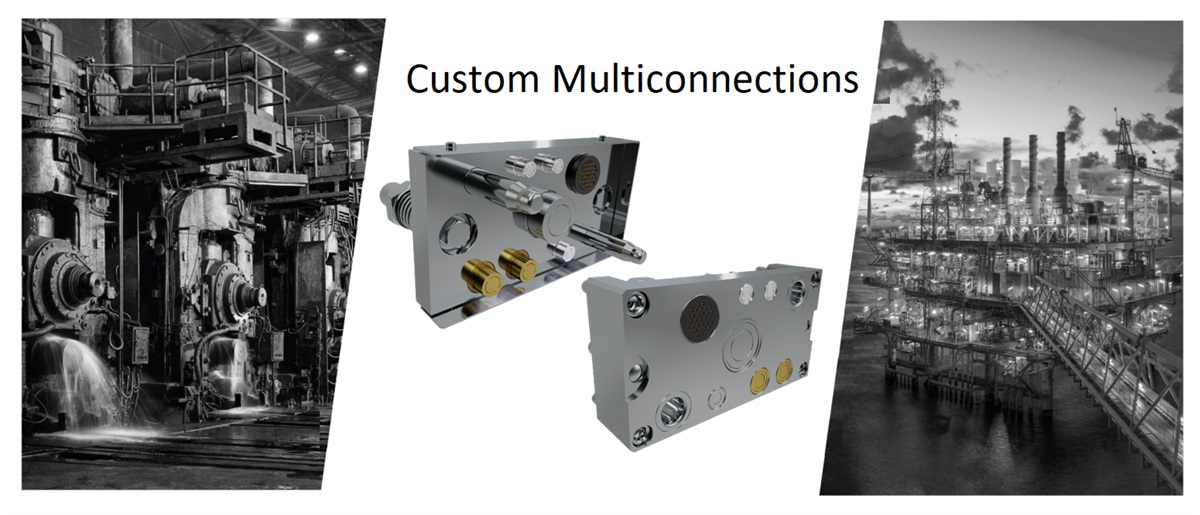

Automatic custom multi-connections are system composed by an upstream plate and a downstream plate who are design to match each other; the first one is in charge of proving fluid and the electricity (for this reason is also called “supply”), the second one receives power from the first one and transfer it to the user (for this reason is also called “receiver”).

One of the two plate is movable and proceeds to the fixed side during the connection process thanks to pneumatic or hydraulic actuators usually installed by the customer.

These plates are assembled with hydraulic couplings, electrical connectors, guiding pins/bushes and floating components on them.

Inaccuracies like offset or angle can be properly compensated; Faster is able to design compensation systems (guiding pins/bushes and floating components) making the plates capable of dealing with the unavoidable wear and tear of the systems in which they are installed, postponing hence the necessity of doing maintenance.

Materials most commonly used for the plates are steel and aluminium with best surface treatments in order to provide proper corrosion resistance.

Streamline Operations: Discover Our Custom Multi-Connection Solutions

Upgrade to automatic custom multi-connections to improve efficiency and reliability in your industrial operations.

Find out more

Selection tips for optimal usage

Each multi-connection, duly integrated into the system in which it is required to work, is the result of different combinations of variables, such as the number of lines, the sizes of couplings and the types of electrical connectors: coupling elements of various nominal diameters and flow rates can be combined with electrical signal, data and power connectors; depending on the intended purpose.

There's a wide variety of fluids potentially being used, from most common ones to technical fluids typical of each specific application, in liquid or gaseous state; Faster can properly address the collection of technical specifications at the correct detail level needed to design products suiting customer’s needs. The zinc-nickel surface treatment and the maximum operating pressures of 250 bar are top-level parameters for the category; many different sizes (from 1/4” to 3”) are available to cover every need of connection of hydraulic lines.

The series of electrical connectors consists of several configurations of long-life multi-pole components matching even the longest cycle time requirements (up to 10^6 cycles). In addition to that, proximity sensors may be provided to detect the connection states in order to integrate such a multi-connection into the control process of a customer’s facility.

Automatic custom multi-connections are not off the shelf products; they are “tailor-made” products that are always customized and produced according to the individual customer requirements. Thanks to their modular design and to Faster’s flexibility, the creation from sketch of a new multi-connection it’s an efficient and fast(er) process!

In summary, automatic custom multi-connections represent a significant leap in industrial connectivity solutions, offering tailor-made, efficient, and reliable systems that cater to the specific demands of various industries.

Ready to learn more about our products?

Our team is here to guide you and offer tailored solutions to fit your needs.

Contact Us